In today’s dynamic global marketplace, optimizing supply chain operations is paramount for business success. Outsourcing supply chain functions presents a strategic avenue for companies to enhance efficiency, reduce costs, and focus on core competencies. This exploration delves into the multifaceted aspects of outsourcing, examining its advantages, disadvantages, and crucial considerations for effective implementation.

From selecting the right third-party provider and negotiating robust service level agreements to leveraging technology for seamless integration and performance monitoring, we’ll navigate the complexities of outsourcing supply chain functions. We will also explore various supply chain activities suitable for outsourcing, alongside those best kept in-house, providing a balanced perspective to inform strategic decision-making.

Technological Aspects of Outsourced Supply Chain Functions

The effective management of outsourced supply chain functions relies heavily on technology. Modern tools and platforms facilitate seamless communication, data sharing, and performance monitoring, ultimately leading to greater efficiency and transparency. This section explores the crucial role of technology in optimizing outsourced supply chain operations.

Technology Facilitates Communication and Collaboration

Effective communication and collaboration are paramount in outsourced supply chain relationships. Real-time communication platforms, such as instant messaging services, video conferencing tools, and collaborative project management software, enable immediate information exchange between internal teams and external partners. This ensures that all stakeholders are aligned on goals, timelines, and potential challenges. For example, a manufacturer outsourcing logistics might use a platform like Slack to instantly communicate shipment updates, address delays, and coordinate actions with its third-party logistics provider.

This reduces misunderstandings and improves response times to unforeseen events.

Supply Chain Management Software Integrates Outsourced Functions

Supply chain management (SCM) software plays a central role in integrating outsourced functions. These platforms provide a centralized system for managing inventory, tracking shipments, monitoring performance indicators, and managing supplier relationships. Features like automated purchase order generation, real-time inventory visibility, and integrated reporting tools streamline operations and minimize manual processes. For instance, an apparel company outsourcing manufacturing might use an SCM system to manage orders, track production progress, and monitor quality control metrics from its overseas factories, all within a single platform.

This enhanced visibility reduces errors and improves overall efficiency.

Data Analytics Monitors and Improves Outsourced Supply Chain Performance

Data analytics provides critical insights into the performance of outsourced supply chain activities. By analyzing data from various sources – such as inventory levels, shipping times, and supplier performance metrics – companies can identify areas for improvement, optimize processes, and mitigate risks. Predictive analytics, for example, can forecast potential disruptions, allowing for proactive mitigation strategies. A company outsourcing warehousing might use data analytics to identify optimal warehouse locations, predict demand fluctuations, and optimize inventory levels, minimizing storage costs and preventing stockouts.

Blockchain Enhances Transparency and Security

Blockchain technology offers a powerful solution for enhancing transparency and security in outsourced supply chain operations. Its decentralized and immutable nature provides a secure record of transactions, enabling all parties to track goods and materials throughout the supply chain. This increased visibility reduces the risk of counterfeiting, fraud, and other security breaches. For example, a food company outsourcing its distribution network could use blockchain to track the origin and movement of its products, ensuring traceability and building consumer trust.

Each step in the supply chain, from farm to table, is recorded on the blockchain, providing verifiable proof of origin and handling. This improves transparency and allows for quicker identification and resolution of any issues.

Managing and Monitoring Outsourced Supply Chain Functions

Effective management and monitoring are crucial for realizing the benefits of outsourcing supply chain functions. Without robust oversight, the potential for cost savings, efficiency gains, and improved service levels can be significantly diminished. This section Artikels strategies for successful management and monitoring, focusing on communication, performance measurement, conflict resolution, and process flow.

Strategies for Effective Communication and Collaboration

Open and consistent communication is the cornerstone of a successful outsourcing partnership. This involves establishing clear communication channels, regular meetings, and well-defined reporting mechanisms. For example, a weekly video conference call can provide a platform for discussing ongoing projects, addressing immediate concerns, and proactively identifying potential issues. Utilizing collaborative project management software allows for real-time updates, shared documentation, and efficient task assignment, promoting transparency and accountability.

Furthermore, establishing a clear escalation path for resolving issues is essential, ensuring that problems are addressed promptly and effectively. This might involve a defined hierarchy of contacts, starting with the primary point of contact and escalating to senior management as needed.

Key Performance Indicators (KPIs) for Monitoring Performance

Monitoring the performance of outsourced functions requires a carefully selected set of KPIs. These metrics should align with the overall supply chain objectives and the specific services outsourced. Examples of relevant KPIs include on-time delivery rate, order accuracy, inventory turnover, lead times, and cost per unit. Regularly tracking and analyzing these KPIs allows for identifying areas of strength and weakness, enabling proactive adjustments to improve performance.

For instance, consistently low on-time delivery rates might indicate a need for improved transportation management or a reevaluation of the supplier’s capacity. The use of dashboards to visualize KPI data can facilitate quick identification of trends and potential problems.

Methods for Resolving Disputes and Managing Conflicts

Disputes and conflicts can arise in any business relationship, including outsourcing partnerships. Having a well-defined dispute resolution process is essential for mitigating the impact of these disagreements. This process should clearly Artikel the steps involved in identifying, addressing, and resolving disputes, including escalation procedures and potential arbitration mechanisms. For example, the contract should specify a process for addressing discrepancies in invoices or quality issues.

Open communication and a collaborative approach are crucial in resolving conflicts, focusing on finding mutually beneficial solutions rather than assigning blame. Regular reviews of the outsourcing agreement and performance can help proactively address potential sources of conflict.

Process Flow Diagram for Managing an Outsourced Supply Chain Function

The following describes a process flow diagram for managing an outsourced supply chain function. Imagine a flowchart with distinct boxes representing each step. The process begins with

- Contract Negotiation and Agreement*, which establishes the scope of work, KPIs, and dispute resolution mechanisms. This is followed by

- Implementation and Onboarding*, where the outsourced provider is integrated into the supply chain. Next,

- Ongoing Monitoring and Performance Review* involves tracking KPIs and conducting regular performance reviews.

- Communication and Collaboration* is an ongoing process throughout the entire lifecycle. Finally,

- Dispute Resolution and Contract Renewal* addresses any conflicts and considers renewing the contract based on performance. This cyclical process ensures continuous improvement and a strong partnership with the third-party provider.

The Supply Chain

Understanding the intricacies of a supply chain is crucial for any organization aiming for efficiency and profitability. A well-managed supply chain ensures the seamless flow of goods and services, from raw material sourcing to final delivery to the end consumer. This section delves into the various stages and components, exploring the influence of globalization and technological advancements, examining successful and unsuccessful strategies, and finally addressing inherent risks and challenges.

Stages and Components of a Typical Supply Chain

A typical supply chain encompasses several key stages, each with its own set of activities and responsibilities. These stages are interconnected and reliant on each other for optimal performance. Disruptions in one area can have a ripple effect throughout the entire chain. The components include sourcing, production, inventory management, logistics, and customer service. Efficient coordination between these components is paramount.

For instance, a delay in sourcing raw materials can directly impact production schedules and lead times, affecting the entire process.

Globalization and Technological Advancements in Modern Supply Chains

Globalization has fundamentally reshaped modern supply chains, enabling businesses to source materials and manufacture products globally. This creates opportunities for cost optimization and access to specialized resources but also introduces complexities in managing geographically dispersed operations and navigating diverse regulatory environments. Technological advancements, such as automation, data analytics, and the Internet of Things (IoT), are transforming supply chain management, offering improved visibility, enhanced efficiency, and increased responsiveness to market demands.

For example, real-time tracking of shipments using IoT devices provides crucial data for proactive risk management.

Examples of Successful and Unsuccessful Supply Chain Strategies

Successful supply chain strategies often prioritize agility, resilience, and collaboration. Companies like Zara, known for its fast fashion model, have excelled by employing a highly responsive supply chain that quickly adapts to changing consumer trends. Conversely, companies that fail to adapt to market changes or lack sufficient visibility into their supply chains often experience significant setbacks. The 2011 Toyota recall, stemming from inadequate quality control and communication within its supply chain, serves as a stark example of the consequences of a poorly managed system.

This event highlighted the importance of transparency and robust quality control measures throughout the entire supply chain.

Risks and Challenges in Supply Chain Management

Organizations face numerous risks and challenges when managing their supply chains. Effective risk mitigation strategies are essential for ensuring business continuity and minimizing potential disruptions.

Supply chain disruptions, such as natural disasters or geopolitical instability, can significantly impact operations and lead to production delays and revenue losses.

Cybersecurity threats pose a growing risk, with potential for data breaches and disruptions to operational systems. This requires robust security measures and contingency plans.

Fluctuations in currency exchange rates and raw material prices can affect profitability and necessitate proactive financial planning and hedging strategies.

Lack of visibility and real-time data can hinder effective decision-making and lead to inefficient inventory management and increased costs.

Globalization and increasing complexity introduce challenges in managing diverse suppliers and coordinating operations across multiple geographical locations.

Successfully outsourcing supply chain functions hinges on meticulous planning, diligent partner selection, and robust monitoring mechanisms. By carefully weighing the benefits and risks, establishing clear communication channels, and leveraging technological advancements, businesses can unlock significant operational gains and achieve a competitive edge. The journey towards a streamlined and optimized supply chain requires a proactive approach, informed choices, and a commitment to continuous improvement.

Helpful Answers

What are the common risks associated with outsourcing supply chain functions?

Common risks include loss of control, potential security breaches, dependency on third-party performance, and challenges in managing communication and coordination.

How can I ensure the confidentiality of my data when outsourcing?

Thorough due diligence on potential partners, robust contracts with clearly defined data security clauses, and regular audits are essential to protect sensitive information.

What are the key performance indicators (KPIs) for monitoring outsourced supply chain functions?

KPIs can include on-time delivery rates, inventory accuracy, cost per unit, lead times, and customer satisfaction scores.

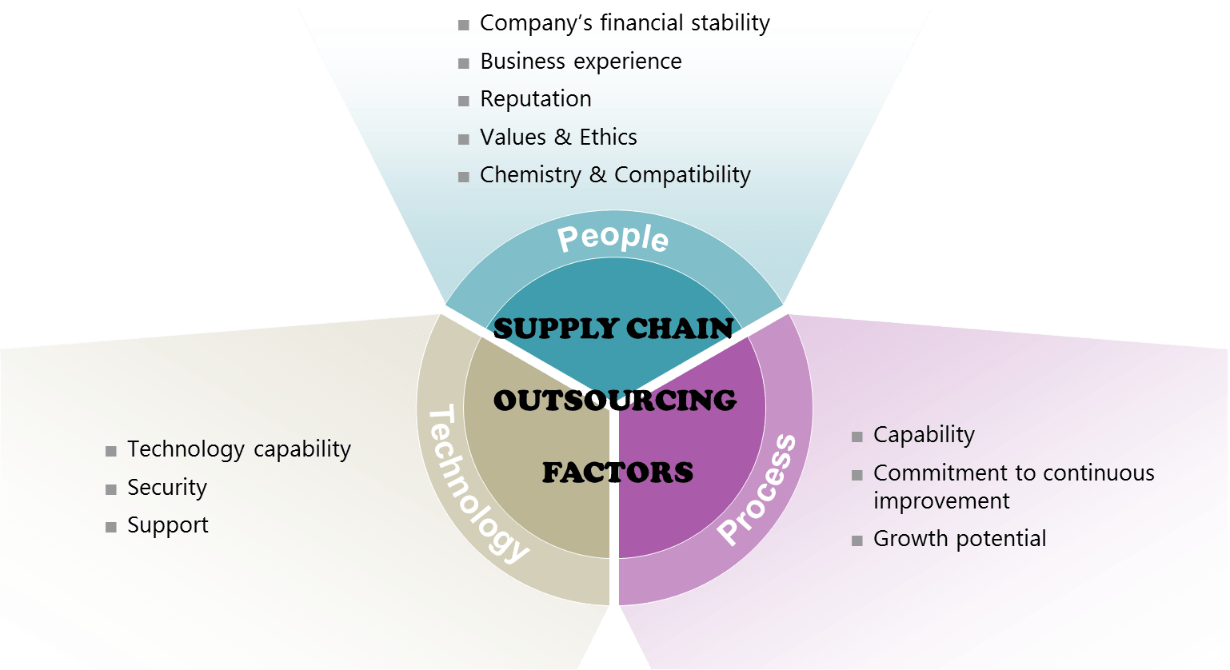

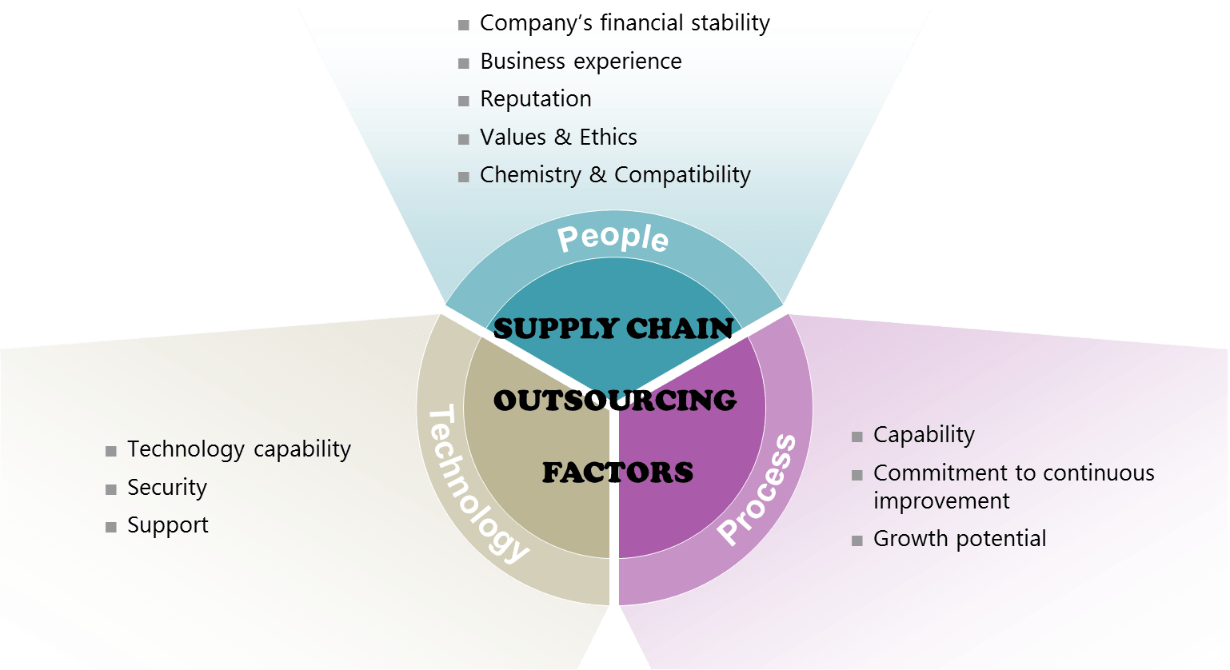

How do I choose the right outsourcing partner?

Consider factors like their experience, reputation, technological capabilities, financial stability, and alignment with your company’s values and goals. Request references and conduct thorough background checks.