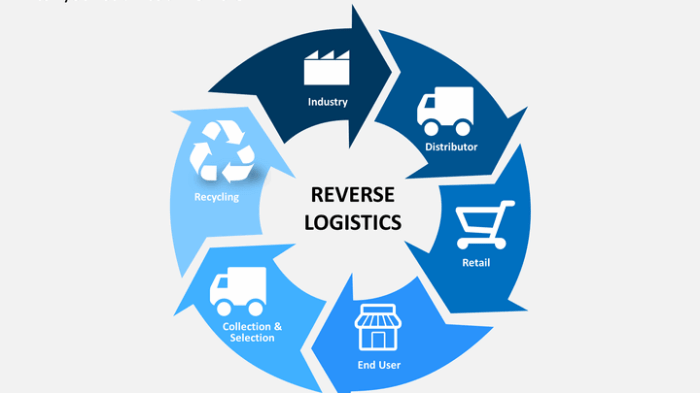

Reverse logistics, the often-overlooked counterpart to forward supply chain operations, is rapidly gaining prominence. It encompasses the planning, implementation, and control of the flow of goods and information from their point of consumption back to their point of origin. This process, encompassing returns, repairs, recycling, and disposal, presents unique challenges and opportunities for businesses seeking efficiency and sustainability. Understanding its complexities is crucial for navigating the modern marketplace and meeting evolving consumer and environmental expectations.

This intricate system involves a delicate balance of cost optimization, environmental responsibility, and customer satisfaction. From managing product returns in e-commerce to orchestrating large-scale product recalls, reverse logistics demands strategic planning and seamless integration with the overall supply chain. Effective reverse logistics strategies can significantly impact a company’s profitability, brand reputation, and its contribution to a circular economy.

Reverse Logistics and Sustainability

Reverse logistics, the process of planning, implementing, and controlling the efficient, cost-effective flow of raw materials, in-process inventory, finished goods, and related information from the point of consumption to the point of origin for the purpose of recapture, recycling, or disposal, plays a crucial role in fostering sustainable business practices. By effectively managing the return and reuse of products and materials, companies can significantly reduce their environmental impact and enhance their corporate social responsibility profile.Reverse logistics offers a powerful mechanism for promoting circular economy principles.

This involves minimizing waste generation through the reuse, remanufacturing, and recycling of products and materials, thus reducing reliance on virgin resources and decreasing landfill waste. Furthermore, efficient reverse logistics systems can lead to cost savings through the recovery of valuable materials and components.

The Role of Reverse Logistics in Promoting Sustainable Practices

Effective reverse logistics strategies are fundamental to implementing sustainable practices. Recycling programs, for instance, rely heavily on efficient reverse logistics to collect, sort, and process materials for reuse. Remanufacturing, the process of restoring used products to like-new condition, also depends on robust reverse logistics to ensure the timely return of products and the efficient management of parts and components.

These processes not only conserve resources but also contribute to a reduced carbon footprint compared to producing new products entirely. Moreover, the efficient handling of e-waste through reverse logistics minimizes the environmental risks associated with improper disposal of electronic devices.

Examples of Companies Successfully Integrating Sustainability into Their Reverse Logistics Strategies

Several companies demonstrate successful integration of sustainability into their reverse logistics. Patagonia, known for its commitment to environmental responsibility, operates a robust Worn Wear program that encourages customers to return used clothing for repair, reuse, or recycling. This program significantly reduces textile waste and extends the lifespan of their products. Similarly, Apple’s recycling program focuses on responsible e-waste management, offering various options for customers to return their old devices for recycling or trade-in.

These initiatives not only promote sustainability but also enhance brand reputation and customer loyalty. Another example is HP’s Planet Partners program, a long-standing initiative focused on recycling and reusing HP cartridges and other products. Their program emphasizes responsible handling of materials and aims to minimize environmental impact throughout the product lifecycle.

The Impact of Extended Producer Responsibility (EPR) Schemes on Reverse Logistics Operations

Extended Producer Responsibility (EPR) schemes significantly impact reverse logistics operations. EPR regulations hold producers responsible for the end-of-life management of their products, incentivizing them to design products for easier recycling and reuse, and to establish efficient reverse logistics systems for collecting and processing end-of-life products. This leads to increased investment in recycling infrastructure and improved waste management practices.

For example, the EU’s Waste Electrical and Electronic Equipment (WEEE) Directive mandates producers to finance the collection and recycling of their products, leading to a more robust and comprehensive e-waste management system across Europe. These schemes effectively shift the responsibility for environmental stewardship from consumers and governments to the producers, fostering innovation and driving the development of more sustainable product designs and end-of-life management strategies.

The Use of Data Analytics to Improve the Environmental Performance of Reverse Logistics

Data analytics plays a vital role in enhancing the environmental performance of reverse logistics. By tracking product returns, analyzing material flows, and identifying areas for improvement, companies can optimize their reverse logistics processes and minimize their environmental footprint. Real-time data on product returns can help identify potential design flaws that lead to frequent failures or repairs. Analyzing the composition of returned products can inform material recovery strategies and enhance recycling efficiency.

Predictive analytics can optimize transportation routes, reducing fuel consumption and emissions. For instance, by analyzing historical data on return rates and product lifecycles, companies can predict future demand for repair parts and optimize inventory levels, reducing waste and storage costs. The use of GPS tracking and sensors in transportation can improve route optimization and reduce fuel consumption, ultimately minimizing the environmental impact of reverse logistics operations.

Supply Chain Integration and Collaboration

Effective reverse logistics is no longer a standalone function but a crucial component of a resilient and efficient supply chain. Integrating it seamlessly improves overall performance, reduces costs, and enhances sustainability efforts. This integration requires careful planning, strong collaboration among stakeholders, and the selection of appropriate reverse logistics models.Reverse logistics significantly contributes to overall supply chain resilience by mitigating risks associated with product returns, recalls, and end-of-life management.

A robust reverse logistics system allows companies to quickly respond to disruptions, minimizing financial losses and reputational damage. For example, a company with a well-established reverse logistics process can efficiently manage a product recall, swiftly retrieving defective products and minimizing negative impact on consumer confidence. This proactive approach builds resilience against unforeseen events and strengthens the entire supply chain’s ability to withstand shocks.

Reverse Logistics Collaboration Models

Several models facilitate collaboration in reverse logistics, each with its own strengths and weaknesses. The choice depends on factors like the company’s size, resources, and the complexity of its reverse logistics operations.

- Partnerships: Collaborative partnerships with suppliers, retailers, and even competitors can streamline reverse logistics. Shared resources, joint planning, and coordinated actions reduce costs and improve efficiency. For instance, a manufacturer might partner with a retailer to jointly manage the return of packaging materials, optimizing transportation and disposal.

- Third-Party Providers (3PLs): Outsourcing reverse logistics operations to 3PLs provides access to specialized expertise and infrastructure. 3PLs can handle various aspects, including transportation, warehousing, repair, and recycling, allowing companies to focus on their core competencies. A company specializing in electronics might contract a 3PL experienced in handling e-waste to manage the environmentally responsible disposal of returned or obsolete products.

- Internal Management: Some companies choose to manage their reverse logistics internally. This approach offers greater control but may require significant investment in infrastructure and expertise. Large companies with extensive resources and a high volume of returns may find internal management more cost-effective in the long run.

Integrating Reverse Logistics into Supply Chain Planning

Integrating reverse logistics into overall supply chain planning improves efficiency by optimizing processes from the initial product design to end-of-life management. This integrated approach allows for better forecasting of returns, more efficient resource allocation, and reduced waste. For example, designing products with ease of disassembly and component reuse in mind reduces costs associated with recycling and disposal at the end of the product’s life cycle.

This proactive approach makes the entire supply chain more efficient.

Best Practices for Fostering Collaboration

Effective collaboration hinges on open communication, shared goals, and mutual trust among stakeholders. Several best practices can foster this collaboration.

- Establish clear communication channels: Regular meetings, shared platforms, and transparent data sharing facilitate information exchange and coordinated decision-making.

- Define roles and responsibilities: Clearly outlining each stakeholder’s role and responsibilities avoids confusion and ensures accountability.

- Develop shared performance metrics: Tracking key performance indicators (KPIs) like return rates, processing times, and recycling rates helps monitor progress and identify areas for improvement.

- Invest in technology: Utilizing technologies like RFID tracking and reverse logistics software enhances visibility and optimizes processes.

- Build strong relationships: Regular interaction, mutual respect, and a collaborative spirit are essential for building trust and fostering long-term partnerships.

Technological Advancements in Reverse Logistics

The efficiency and effectiveness of reverse logistics are significantly impacted by technological advancements. These innovations streamline processes, reduce costs, and improve sustainability efforts across the entire return lifecycle. From initial product return to final disposal or refurbishment, technology plays a crucial role in optimizing each stage.

RFID and Barcode Technology for Tracking Returned Goods

RFID (Radio-Frequency Identification) and barcode technologies are fundamental for tracking returned goods throughout the reverse logistics process. Barcodes provide a basic level of identification, allowing for the scanning and recording of individual items. However, RFID tags offer superior capabilities. RFID tags can be read without line-of-sight, allowing for faster and more efficient tracking of multiple items simultaneously. This is particularly beneficial in high-volume return centers where manually scanning each barcode would be incredibly time-consuming.

For example, a large clothing retailer could use RFID tags on garments to track returns from various stores, quickly identifying damaged or unsalvageable items for appropriate processing. The real-time tracking provided by RFID improves inventory management, reduces processing times, and minimizes the risk of loss or misplacement.

Data Analytics for Optimizing Reverse Logistics Decision-Making

Data analytics plays a vital role in optimizing reverse logistics. By collecting and analyzing data from various sources, including returns processing systems, customer feedback, and transportation data, companies gain valuable insights into return patterns, product defects, and customer behavior. This data can be used to identify areas for improvement, such as optimizing transportation routes, improving product design to reduce returns, and enhancing customer service to prevent returns.

For instance, analyzing return data might reveal that a particular product consistently malfunctions, prompting a redesign to address the defect and prevent future returns. Predictive analytics can also forecast return volumes, allowing for more efficient resource allocation and improved inventory management.

Automation Technologies for Improving Reverse Logistics Efficiency

Automation technologies, such as robotics and automated sorting systems, are significantly improving the efficiency of reverse logistics operations. Robotics can automate tasks such as unloading returned goods, sorting items based on their condition, and repackaging products for resale or recycling. Automated sorting systems use various technologies, including computer vision and machine learning, to identify and sort items quickly and accurately.

This automation reduces labor costs, improves processing speed, and minimizes human error. Consider a large electronics retailer using robotic arms to efficiently sort returned electronics based on their functionality and damage level. This automation drastically reduces processing time and allows for quicker refurbishment or recycling of returned items.

Software Solutions Supporting Reverse Logistics Management

Numerous software solutions are designed specifically to support reverse logistics management. These systems integrate various aspects of the reverse logistics process, providing a centralized platform for managing returns, tracking inventory, and analyzing data. Features often include return authorization management, automated workflows for processing returns, and real-time visibility into the entire reverse logistics process. A software solution might automate the generation of return labels, track the location of returned goods, and provide reporting on key performance indicators (KPIs) such as return rates and processing times.

The use of such software enables better decision-making, improved efficiency, and reduced costs associated with managing returns. For example, a company could use a software system to track the environmental impact of its reverse logistics operations, allowing them to identify areas for improvement in sustainability.

Measuring the Performance of Reverse Logistics

Effective reverse logistics is crucial for minimizing costs, enhancing sustainability, and improving customer satisfaction. Measuring its performance requires a robust system of Key Performance Indicators (KPIs) and a structured approach to data collection and analysis. This allows businesses to identify areas for improvement and optimize their reverse logistics processes for greater efficiency and profitability.

Key Performance Indicators (KPIs) for Reverse Logistics

Several key performance indicators are vital for evaluating the effectiveness of reverse logistics operations. These metrics provide a quantifiable measure of success and help identify areas needing improvement. Choosing the right KPIs depends on the specific goals and challenges of the reverse logistics program.

| KPI | Calculation Method | Interpretation | Example |

|---|---|---|---|

| Return Rate | (Number of returned items / Total number of items sold) – 100 | Indicates the percentage of products returned. High rates may signal product quality issues or poor customer service. | A return rate of 5% suggests that for every 100 items sold, 5 are returned. |

| Reverse Logistics Cost | Total cost of reverse logistics activities (transportation, processing, disposal, etc.) divided by the number of returned items or total revenue. | Measures the overall cost-effectiveness of the reverse logistics process. Lower costs indicate better efficiency. | A reverse logistics cost of $5 per returned item shows the average expense associated with each return. |

| Return Processing Time | Average time taken to process a returned item, from receipt to final disposition (refund, repair, recycling, etc.). | Indicates the speed and efficiency of the return process. Shorter processing times improve customer satisfaction. | An average processing time of 3 days signifies efficient handling of returns. |

| Customer Satisfaction with Returns | Measured through surveys, feedback forms, and customer reviews focusing on aspects like ease of return, communication, and resolution time. | Reflects customer perception of the reverse logistics process. High satisfaction scores indicate a well-designed and effective system. | A customer satisfaction score of 85% indicates positive customer sentiment towards the return process. |

Tracking and Analyzing Reverse Logistics Costs and Efficiency

Accurate cost tracking is fundamental to understanding the financial performance of reverse logistics. This involves categorizing costs into specific activities like transportation, handling, inspection, repair, and disposal. Cost analysis should compare costs across different time periods, product categories, and return reasons to identify areas of inefficiency. Utilizing software designed for supply chain management can greatly aid in this process by automating data collection and providing advanced analytical tools.

For example, a company might track the cost per unit for different transportation methods to optimize shipping costs. Analyzing data on processing times for various product types could highlight bottlenecks in the return process.

Measuring Customer Satisfaction with the Reverse Logistics Process

Measuring customer satisfaction is crucial for improving the overall reverse logistics experience. A multi-faceted approach is recommended, including:

- Post-return surveys: These surveys should ask specific questions about the ease of initiating a return, the clarity of instructions, the speed of processing, and the overall experience. They should use a Likert scale (e.g., strongly agree to strongly disagree) to quantify satisfaction.

- Feedback forms: Providing a simple online or paper-based form allows customers to provide detailed feedback on their experience.

- Customer reviews: Monitoring online reviews on platforms like social media and review websites can provide valuable insights into customer perceptions.

- Net Promoter Score (NPS): This metric gauges customer loyalty by asking customers how likely they are to recommend the company’s return process to others.

Analyzing this data will pinpoint areas needing improvement, allowing for targeted changes to enhance customer satisfaction and loyalty. For example, consistently negative feedback about unclear return instructions suggests a need for simplified and more user-friendly documentation.

The Future of Reverse Logistics

Reverse logistics is poised for significant transformation, driven by technological advancements, evolving consumer expectations, and a growing emphasis on sustainability. The future will see a shift towards more proactive, integrated, and data-driven approaches, optimizing resource recovery and minimizing environmental impact. This evolution will be shaped by several key factors, including the increasing adoption of circular economy principles and the development of innovative technologies.The integration of emerging technologies will fundamentally alter reverse logistics operations.

Artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) will play crucial roles in optimizing various stages of the reverse supply chain, from product return management to material recovery and recycling. These technologies will improve forecasting accuracy, enhance process automation, and provide greater visibility throughout the entire reverse logistics process.

Emerging Technologies and Trends in Reverse Logistics

The convergence of AI, ML, and IoT is creating opportunities for significant improvements in reverse logistics efficiency and sustainability. AI-powered predictive analytics can forecast return rates more accurately, enabling businesses to optimize inventory levels and reduce warehousing costs. ML algorithms can analyze large datasets to identify patterns and trends in product returns, helping companies proactively address potential quality issues or design flaws.

IoT-enabled devices, such as smart packaging and sensors, can track products throughout the return process, providing real-time visibility and improving accountability. For example, a clothing retailer might use IoT sensors in garments to track their condition during returns, enabling them to identify damaged items quickly and sort them appropriately for repair, reuse, or recycling.

Innovative Reverse Logistics Solutions

Several innovative solutions are emerging to address the challenges and opportunities in reverse logistics. One example is the rise of reverse vending machines, which allow consumers to easily return packaging or used products for recycling or reuse. These machines often offer incentives, such as discounts or rewards points, encouraging consumer participation. Another example is the development of closed-loop supply chains, where products are designed for easy disassembly and recycling, allowing for the recovery of valuable materials and components.

Companies like Patagonia are pioneering this approach, offering repair and take-back programs for their products, promoting durability and reducing waste.

The Circular Economy’s Impact on Reverse Logistics

The circular economy model, which emphasizes resource efficiency and waste reduction, is fundamentally changing the landscape of reverse logistics. Instead of viewing returned products as waste, the circular economy encourages their reuse, repair, remanufacturing, or recycling. This shift requires a more integrated approach to product design, manufacturing, and reverse logistics, ensuring that products are designed for circularity from the outset.

This proactive approach reduces the environmental impact associated with waste disposal and creates new opportunities for resource recovery and value creation. For example, a company producing electronic devices might design them with modular components that can be easily replaced or recycled, extending product lifespan and minimizing e-waste.

The Future Role of Reverse Logistics in Sustainable Supply Chain Management

Reverse logistics will play a crucial role in creating truly sustainable supply chains. By optimizing the recovery and reuse of materials, reducing waste, and minimizing environmental impact, reverse logistics contributes directly to corporate sustainability goals and enhances a company’s environmental, social, and governance (ESG) profile. The increasing demand for sustainable practices from consumers and investors will drive further innovation and investment in reverse logistics technologies and processes.

Companies that effectively integrate sustainable reverse logistics practices into their overall supply chain strategy will gain a competitive advantage in the marketplace. For instance, a company prioritizing sustainability might invest in developing a comprehensive take-back program for its products, offering incentives for returns and ensuring responsible recycling or reuse of materials. This demonstrates a commitment to environmental responsibility and can enhance the company’s brand reputation and attract environmentally conscious consumers.

In conclusion, mastering reverse logistics is no longer a luxury but a necessity for businesses striving for operational excellence and sustainable growth. By embracing technological advancements, fostering collaboration across the supply chain, and prioritizing data-driven decision-making, companies can transform their reverse logistics operations from a cost center into a strategic advantage. The future of reverse logistics lies in creating truly circular supply chains, minimizing waste, maximizing resource utilization, and enhancing overall sustainability.

The journey toward this future requires continuous innovation, adaptation, and a commitment to environmental responsibility.

Essential FAQs

What are the key performance indicators (KPIs) used to measure reverse logistics effectiveness?

Common KPIs include return rate, processing time, cost per return, customer satisfaction with the return process, and the percentage of materials recycled or reused.

How can technology improve the efficiency of reverse logistics?

Technologies such as RFID and barcode scanning improve tracking and inventory management. Data analytics provides insights for optimizing processes. Automation, including robotics, streamlines handling and processing of returned goods.

What is the role of extended producer responsibility (EPR) in reverse logistics?

EPR schemes hold producers responsible for the end-of-life management of their products, incentivizing them to design for recyclability and invest in effective reverse logistics systems.

How can companies improve customer satisfaction with their reverse logistics processes?

Clear return policies, easy-to-use online return portals, fast processing times, and proactive communication with customers are key to enhancing customer satisfaction.