The global supply chain, a complex web of interconnected businesses, faces persistent challenges: lack of transparency, security vulnerabilities, and inefficient processes. Blockchain technology, with its immutable ledger and decentralized nature, offers a transformative solution. This exploration delves into the practical applications of blockchain across diverse supply chains, examining its impact on traceability, security, and overall efficiency. We’ll explore real-world examples and analyze the benefits, challenges, and future potential of this revolutionary technology.

From enhancing food safety by tracking produce from farm to table to securing pharmaceutical supply chains against counterfeiting, blockchain’s potential is vast. This overview will dissect how smart contracts automate processes, improve trust among stakeholders, and ultimately, streamline operations. We will also consider the various blockchain architectures suitable for different supply chain needs and address potential hurdles to widespread adoption.

Introduction to Supply Chain Blockchain Applications

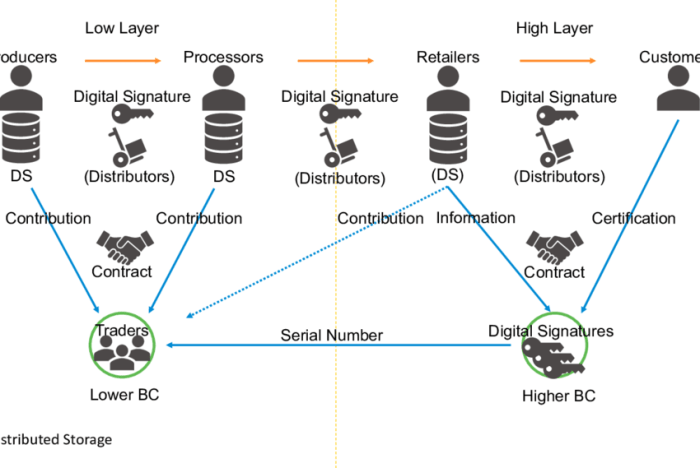

Blockchain technology, initially known for its role in cryptocurrencies, offers a transformative potential for supply chain management. Its decentralized and immutable ledger system provides a transparent and secure way to track goods and information throughout the entire supply chain, from origin to consumer. This enhanced transparency and security addresses many of the long-standing challenges inherent in traditional supply chain operations.Blockchain’s core functionality relies on a distributed network of computers maintaining a shared, encrypted database.

Each transaction is recorded as a “block” and linked cryptographically to the previous block, forming a chain. This structure makes it extremely difficult to alter or delete information without detection, ensuring data integrity and authenticity. This inherent trust and transparency are particularly valuable in supply chain management, where trust and visibility are often lacking.

Challenges Addressed by Blockchain in Supply Chains

Traditional supply chains often suffer from a lack of transparency, leading to inefficiencies and vulnerabilities. Data is often siloed across different organizations, making it difficult to track products and verify their authenticity. This lack of visibility can lead to delays, counterfeiting, and difficulties in responding to recalls or disruptions. Furthermore, manual processes are prone to errors and fraud, adding further complexity and cost.

Blockchain technology directly addresses these issues by providing a shared, immutable record of all transactions and events within the supply chain. This shared view allows all participants to access the same information, fostering collaboration and trust.

Examples of Blockchain Implementation in Different Supply Chains

Blockchain’s versatility allows for its application across various industries and supply chain models.

Blockchain in the Food Industry

The food industry is a prime example of where blockchain can significantly improve traceability and safety. Imagine a system where consumers can scan a QR code on a product and instantly access its entire journey, from farm to table. This includes information on the farm’s location, harvesting date, processing methods, and transportation details. This enhanced transparency builds consumer confidence and enables faster and more effective recall processes in case of contamination.

For example, Walmart has piloted a blockchain-based system to track the origin and movement of its leafy greens, significantly reducing the time it takes to trace products in case of a recall.

Blockchain in Pharmaceutical Supply Chains

The pharmaceutical industry faces significant challenges with counterfeiting and the need for stringent quality control. Blockchain can help track pharmaceuticals throughout their journey, verifying their authenticity and preventing the distribution of counterfeit drugs. This is crucial for ensuring patient safety and protecting the integrity of the supply chain. Several pharmaceutical companies are already exploring blockchain solutions to improve drug traceability and combat counterfeiting.

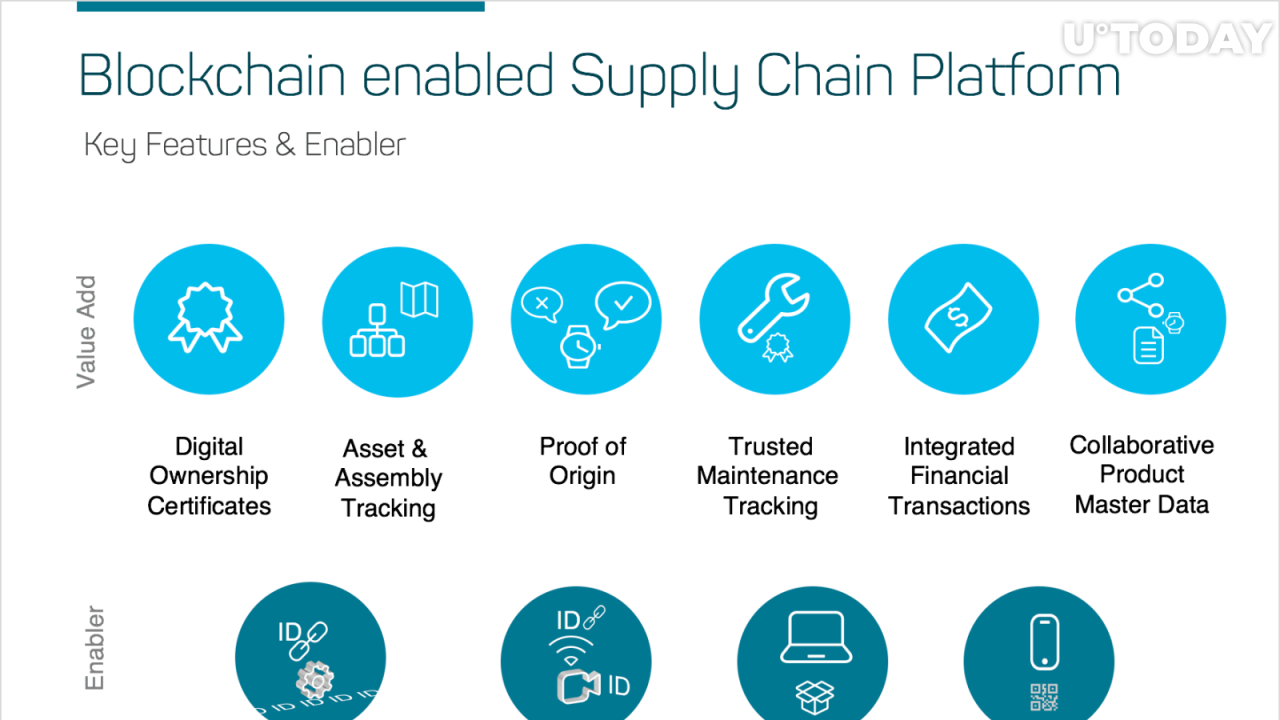

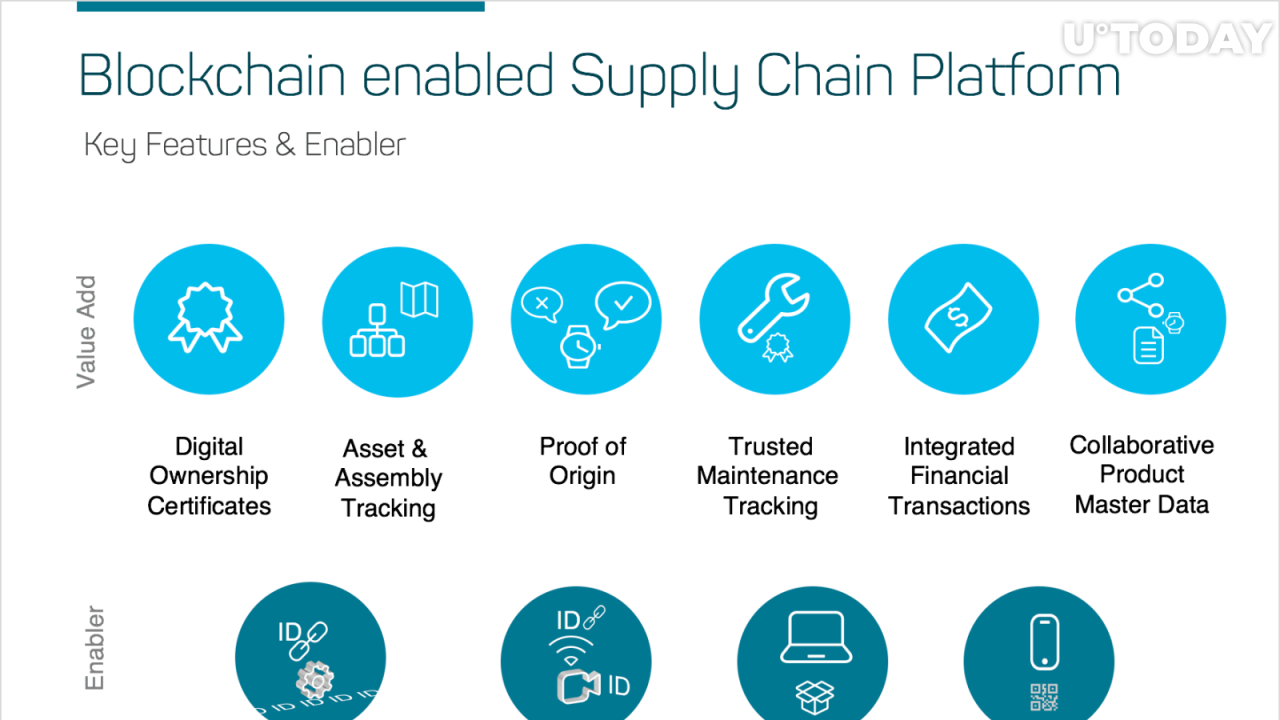

Blockchain in Manufacturing Supply Chains

Manufacturing supply chains often involve complex networks of suppliers and manufacturers. Blockchain can improve the efficiency and transparency of these networks by providing a shared platform for tracking materials, components, and finished goods. This can streamline production processes, reduce waste, and improve overall supply chain visibility. For instance, a manufacturer could use blockchain to track the origin and quality of raw materials, ensuring compliance with sustainability and ethical sourcing standards.

This increased transparency also helps in identifying bottlenecks and optimizing the manufacturing process.

Benefits and Challenges of Implementing Blockchain in Supply Chains

Implementing blockchain technology in supply chain management presents a transformative opportunity, promising increased efficiency, transparency, and trust. However, realizing this potential requires careful consideration of both the advantages and the hurdles involved in its adoption. This section will explore the key benefits and challenges associated with blockchain implementation in supply chains.

Key Benefits of Blockchain in Supply Chain Management

The application of blockchain technology offers several significant advantages for supply chain operations. These improvements can lead to substantial cost savings, streamlined processes, and increased confidence among stakeholders.

- Cost Reduction: Blockchain can automate many manual processes, reducing labor costs associated with data entry, reconciliation, and verification. For example, eliminating the need for intermediaries in certain transactions can directly lower costs. The increased efficiency also minimizes waste and loss due to improved inventory management and traceability.

- Improved Efficiency: Real-time data visibility across the entire supply chain allows for faster decision-making and improved responsiveness to market changes. Automated tracking and tracing of goods reduces delays and improves the overall flow of goods and information.

- Enhanced Trust and Transparency: The immutable nature of blockchain creates a shared, transparent record of transactions, fostering trust among all participants. This increased transparency helps to prevent fraud, counterfeiting, and disputes by providing a verifiable audit trail of every step in the supply chain.

- Improved Traceability and Product Recall Management: Blockchain enables detailed tracking of products from origin to consumer. In the event of a product recall, this traceability allows for quick and efficient identification and removal of affected products, minimizing potential damage to brand reputation and consumer safety.

- Enhanced Security: Cryptographic hashing and decentralized storage significantly enhance the security of supply chain data, reducing the risk of data breaches and tampering.

Comparison of Blockchain Architectures for Supply Chain Applications

Different blockchain architectures offer varying levels of control, transparency, and scalability, making the choice of architecture crucial for successful implementation.

| Architecture Type | Description | Advantages | Disadvantages |

|---|---|---|---|

| Public Blockchain | Open and permissionless; anyone can participate and view transactions. | High transparency, decentralization, and security. | Scalability issues, potential for slower transaction speeds, and vulnerability to attacks. |

| Private Blockchain | Permissioned; access and participation are controlled by a central authority. | High control, faster transaction speeds, and better scalability compared to public blockchains. | Less transparency, potential for centralization risks, and reduced trust among participants if not managed properly. |

| Consortium Blockchain | Permissioned; multiple organizations collaborate and share control. | Balances transparency and control, improved scalability compared to public blockchains, and fosters collaboration among participants. | Requires consensus mechanisms among participating organizations, potential for conflicts in governance, and complexity in setup and management. |

Challenges of Implementing Blockchain in Supply Chains

Despite the numerous benefits, several challenges hinder widespread blockchain adoption in supply chains. Addressing these issues is crucial for realizing the full potential of this technology.

- Interoperability Issues: Different blockchain platforms often lack compatibility, making it difficult to integrate data across various parts of the supply chain. Solutions include developing standardized protocols and data formats, or utilizing middleware to bridge the gaps between different blockchain systems.

- Scalability Limitations: Some blockchain platforms struggle to handle the large volumes of data generated by complex supply chains. Solutions involve exploring more scalable blockchain architectures, optimizing transaction processing, and employing sharding or other scalability solutions.

- Regulatory Hurdles: The regulatory landscape surrounding blockchain technology is still evolving, creating uncertainty and hindering adoption in some sectors. Solutions include engaging with regulators to clarify guidelines and advocate for policies that support blockchain innovation.

- Integration Complexity: Integrating blockchain into existing supply chain systems can be complex and costly, requiring significant technical expertise and resources. Solutions include phased implementation, leveraging existing enterprise resource planning (ERP) systems, and selecting user-friendly blockchain platforms.

- Cost of Implementation: The initial investment in blockchain infrastructure, software, and personnel can be substantial, particularly for smaller companies. Solutions involve exploring cost-effective blockchain solutions, seeking government grants or subsidies, and focusing on high-value use cases with clear ROI.

Blockchain’s integration into supply chain management signifies a paradigm shift, promising greater transparency, security, and efficiency. While challenges remain regarding scalability and interoperability, the potential benefits—including reduced costs, improved traceability, and enhanced trust—are compelling. As technology evolves and adoption increases, we can anticipate a future where blockchain becomes an integral component of global supply chains, fostering greater resilience and sustainability across industries.

Answers to Common Questions

What are the main privacy concerns with blockchain in supply chains?

Data privacy is a key concern. While blockchain is transparent, careful consideration of data access controls and encryption techniques is crucial to protect sensitive information. Permissioned blockchains offer more control over data visibility compared to public blockchains.

How does blockchain reduce counterfeiting?

Blockchain creates an immutable record of a product’s journey, from origin to consumer. This makes it difficult to counterfeit products as any alteration to the chain of custody would be easily detectable.

What is the cost of implementing blockchain in a supply chain?

Implementation costs vary significantly depending on the complexity of the supply chain, the chosen blockchain platform, and the level of integration required. Initial investment can be substantial, but potential long-term cost savings from increased efficiency and reduced fraud often outweigh the initial expenditure.

What are some examples of blockchain platforms used in supply chains?

Hyperledger Fabric, R3 Corda, and Ethereum are among the popular blockchain platforms used for supply chain applications. The choice of platform depends on specific needs and requirements.