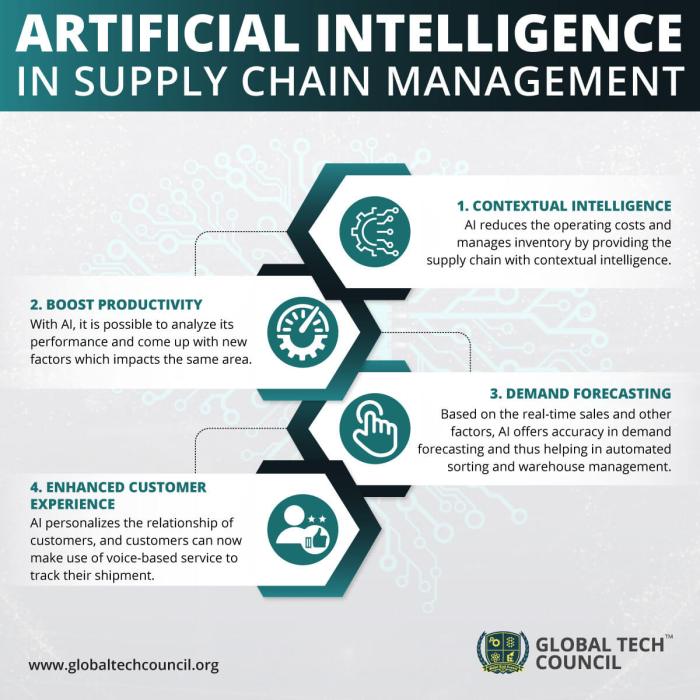

Artificial intelligence (AI) is rapidly transforming supply chain management, offering unprecedented opportunities for efficiency, optimization, and resilience. From predictive analytics for demand forecasting to autonomous warehouse robots and real-time tracking of goods, AI is reshaping every aspect of how businesses move products from origin to consumer. This exploration delves into the current state of AI adoption, highlighting both the immense potential and the challenges inherent in its implementation.

This examination covers key applications, including AI-powered planning, optimization strategies, enhanced visibility, and future trends. We will analyze how AI is improving decision-making, reducing costs, minimizing risks, and ultimately creating more agile and responsive supply chains. The discussion will also address ethical considerations and the role of AI in building a more sustainable future for the industry.

Introduction to AI in Supply Chain Management

Artificial intelligence (AI) is rapidly transforming various industries, and supply chain management is no exception. The integration of AI is still in its relatively early stages, but its adoption is accelerating, driven by the need for increased efficiency, resilience, and profitability in increasingly complex global supply chains. While widespread, complete AI integration remains a future goal, many companies are already leveraging AI-powered tools and techniques to optimize specific aspects of their operations.The potential benefits of incorporating AI into supply chain operations are substantial.

By analyzing vast amounts of data from various sources – including sales forecasts, inventory levels, transportation routes, and market trends – AI algorithms can identify patterns and predict future outcomes with greater accuracy than traditional methods. This improved predictive capability enables businesses to make more informed decisions, leading to significant improvements across the entire supply chain.

Current State of AI Adoption in Supply Chain Management

Many companies are currently experimenting with AI solutions focusing on specific areas. For instance, predictive maintenance using machine learning algorithms helps anticipate equipment failures, minimizing downtime and reducing maintenance costs. Similarly, AI-powered demand forecasting tools leverage historical sales data and external factors to predict future demand more accurately, enabling better inventory management and reducing stockouts or overstocking. The use of AI in logistics optimization, such as route planning and delivery scheduling, is also growing, leading to reduced transportation costs and improved delivery times.

However, widespread, fully integrated AI systems across entire supply chains remain less common, due to the significant challenges involved.

Potential Benefits of Integrating AI into Supply Chain Operations

AI offers a wide range of benefits, leading to improved efficiency and profitability. For example, AI-powered optimization engines can significantly reduce transportation costs by identifying the most efficient routes and modes of transport. Furthermore, AI can improve inventory management by accurately predicting demand, leading to reduced warehousing costs and minimizing stockouts. Real-time visibility into the supply chain, provided by AI-powered tracking systems, enables proactive issue resolution, reducing disruptions and delays.

Finally, AI can enhance decision-making by providing data-driven insights, allowing businesses to respond more effectively to changing market conditions and unforeseen events. A specific example would be a retailer using AI to predict a surge in demand for a particular product during a holiday season, enabling them to proactively increase inventory and avoid stockouts.

Challenges Associated with Implementing AI in Supply Chain Management

Despite the potential benefits, implementing AI in supply chain management presents significant challenges. Data integration is a major hurdle, as AI algorithms require access to large, high-quality datasets from various sources, which often necessitates significant investment in data infrastructure and cleaning. Another challenge lies in the complexity of AI algorithms and the need for specialized expertise to develop, deploy, and maintain them.

The high cost of implementation, including software licenses, hardware infrastructure, and skilled personnel, can also be prohibitive for some businesses. Finally, ensuring data security and privacy is crucial, as AI systems often handle sensitive business information. For example, a company implementing AI-powered demand forecasting might struggle with integrating data from disparate systems (e.g., ERP, CRM, and point-of-sale systems) or might face challenges in ensuring the accuracy and completeness of the data used for training the AI model.

AI Applications in Supply Chain Planning

AI is rapidly transforming supply chain planning, enabling businesses to make more informed decisions, optimize operations, and improve overall efficiency. By leveraging the power of machine learning and predictive analytics, organizations can gain a significant competitive advantage in today’s dynamic market. This section will explore several key applications of AI in this critical area.

AI-Powered Demand Forecasting Techniques

Accurate demand forecasting is paramount for effective supply chain planning. Traditional methods often struggle to account for the complexity of modern market dynamics. AI algorithms, however, can analyze vast datasets encompassing historical sales data, market trends, economic indicators, social media sentiment, and even weather patterns to generate significantly more precise forecasts. Examples include time series analysis using techniques like ARIMA (Autoregressive Integrated Moving Average) enhanced with machine learning for improved accuracy, and deep learning models like recurrent neural networks (RNNs) and long short-term memory (LSTM) networks capable of capturing complex temporal dependencies in demand patterns.

For instance, a retailer using LSTM could predict seasonal fluctuations in demand for winter coats with greater accuracy than traditional methods, leading to optimized inventory levels and reduced stockouts or overstocking.

AI-Driven Inventory Management Strategies

AI optimizes inventory management by dynamically adjusting inventory levels based on real-time demand fluctuations and other relevant factors. Machine learning algorithms can analyze historical data to identify patterns and predict future demand, enabling businesses to maintain optimal stock levels while minimizing storage costs and reducing the risk of stockouts or excess inventory. This includes the implementation of AI-powered inventory optimization systems that leverage techniques like reinforcement learning to automatically adjust reorder points and order quantities based on changing conditions.

A successful example might be an automotive parts supplier using an AI system to predict fluctuations in demand for specific components based on vehicle production schedules and sales forecasts, ensuring timely delivery and avoiding costly production delays.

AI-Driven System for Production Planning and Scheduling

An AI-driven production planning and scheduling system can significantly enhance efficiency and reduce production lead times. These systems utilize machine learning algorithms to analyze historical production data, machine capacity, and order details to create optimized production schedules. They can also incorporate real-time data from the factory floor to adapt to unexpected events, such as machine breakdowns or material shortages.

The system might employ constraint programming or mixed-integer programming techniques, enhanced with machine learning for predictive maintenance and dynamic scheduling adjustments. For example, a manufacturing plant producing electronics could use such a system to optimize its assembly line operations, dynamically adjusting the production schedule in response to changes in component availability or demand for specific product models, leading to reduced production costs and improved on-time delivery.

Comparison of AI Algorithms for Supply Chain Planning

Various AI algorithms are applicable to supply chain planning, each with its strengths and weaknesses. A comparison might include:

| Algorithm | Strengths | Weaknesses | Applications |

|---|---|---|---|

| Linear Regression | Simple, interpretable | Assumes linear relationships | Basic demand forecasting |

| Support Vector Machines (SVM) | Effective in high-dimensional spaces | Can be computationally expensive | Classification of demand patterns |

| Neural Networks (e.g., RNN, LSTM) | Can model complex non-linear relationships | Requires large datasets, can be difficult to interpret | Advanced demand forecasting, anomaly detection |

| Reinforcement Learning | Adapts to dynamic environments | Requires significant computational resources and careful design | Inventory optimization, dynamic routing |

Choosing the most suitable algorithm depends on factors such as the complexity of the problem, the size and quality of the available data, and the computational resources available. Often, a hybrid approach combining multiple algorithms yields the best results.

AI for Supply Chain Optimization

AI is revolutionizing supply chain management by enabling significant improvements in efficiency, cost reduction, and overall performance. Through advanced analytics and predictive capabilities, AI algorithms optimize various aspects of the supply chain, leading to streamlined operations and enhanced decision-making. This section will explore several key areas where AI is driving optimization.

Machine Learning for Route Optimization and Logistics

Machine learning algorithms excel at analyzing vast datasets to identify optimal routes for transportation. Factors such as traffic patterns, weather conditions, fuel prices, and delivery deadlines are considered to minimize transit times and transportation costs. For instance, algorithms can dynamically adjust routes in real-time based on unforeseen events like traffic congestion or road closures, ensuring timely deliveries. This results in significant savings in fuel consumption and reduced delivery times, ultimately enhancing customer satisfaction.

Furthermore, predictive modeling can forecast potential delays and proactively suggest alternative routes, minimizing disruptions to the supply chain.

AI in Warehouse Automation and Robotics

AI-powered warehouse automation significantly improves efficiency and reduces operational costs. Robotics, guided by AI, automate tasks such as picking, packing, and sorting, increasing throughput and minimizing human error. AI algorithms optimize warehouse layouts and inventory management, ensuring efficient storage and retrieval of goods. Computer vision systems, integrated with AI, identify and track items, improving inventory accuracy and reducing stockouts.

For example, automated guided vehicles (AGVs) navigate warehouses autonomously, transporting goods between different locations, while robotic arms perform precise picking and packing operations with speed and accuracy far exceeding human capabilities. This automation leads to increased productivity, reduced labor costs, and improved order fulfillment times.

Case Study: AI-Driven Inventory Optimization at a Retail Giant

A major retailer implemented an AI-powered inventory management system to optimize stock levels across its vast network of stores. The system analyzed historical sales data, consumer demand forecasts, and various external factors to predict future demand with greater accuracy. This enabled the retailer to optimize inventory levels, reducing stockouts and minimizing excess inventory. The result was a significant reduction in warehousing costs, improved customer satisfaction due to increased product availability, and a substantial increase in overall profitability.

The AI system also identified slow-moving items, enabling the retailer to adjust its purchasing strategies and minimize losses.

AI in Supply Chain Risk Management and Mitigation

AI plays a crucial role in identifying and mitigating potential risks within the supply chain. Machine learning algorithms analyze various data sources, including weather patterns, geopolitical events, and economic indicators, to predict potential disruptions. For example, an AI system could identify the risk of a port closure due to a severe storm and suggest alternative shipping routes or storage locations.

This proactive risk assessment enables businesses to develop contingency plans and minimize the impact of unforeseen events. Moreover, AI can analyze historical data to identify patterns and trends related to specific risks, enabling the development of more robust and effective risk management strategies. This proactive approach minimizes disruptions, reduces financial losses, and enhances the resilience of the supply chain.

AI and Supply Chain Visibility

AI significantly enhances supply chain visibility, providing real-time insights into the movement and status of goods, improving efficiency, and minimizing disruptions. This increased transparency allows businesses to make data-driven decisions, optimize operations, and ultimately, enhance customer satisfaction.AI enhances real-time tracking and monitoring of goods through the integration of various technologies such as RFID, GPS, and IoT sensors. This data is then processed and analyzed by AI algorithms to provide a comprehensive overview of the supply chain’s status.

For instance, a company can track a shipment’s location in real-time, anticipate potential delays based on traffic patterns or weather conditions, and proactively adjust delivery schedules.

Real-time Tracking and Monitoring of Goods

AI algorithms analyze data from various sources, including GPS trackers on vehicles, RFID tags on pallets, and IoT sensors in warehouses, to provide real-time updates on the location and condition of goods throughout the supply chain. Machine learning models can identify patterns and anomalies, flagging potential issues like delays, damage, or theft. This allows for immediate intervention and mitigation of risks, preventing significant disruptions and losses.

For example, if a shipment is deviating from its planned route, the AI system can alert relevant personnel, allowing them to investigate and take corrective action.

Predictive Maintenance of Equipment and Infrastructure

AI enables predictive maintenance by analyzing data from various sources, including sensor data from equipment and historical maintenance records. Machine learning models identify patterns that indicate potential equipment failures, allowing for proactive maintenance scheduling. This minimizes downtime, reduces repair costs, and extends the lifespan of equipment. For example, an AI system monitoring a conveyor belt in a warehouse might detect subtle changes in its vibration patterns, predicting a potential bearing failure days in advance, allowing for preventative maintenance before a costly breakdown occurs.

Improving Supply Chain Communication and Collaboration

AI facilitates improved communication and collaboration within the supply chain by automating tasks such as data sharing and reporting. AI-powered chatbots can provide real-time updates to stakeholders, answer frequently asked questions, and resolve simple issues. This improves transparency and reduces the need for manual intervention, freeing up human resources for more strategic tasks. For example, a chatbot can automatically notify a supplier of an impending delay in receiving raw materials, allowing them to adjust their production schedule accordingly.

Additionally, AI can analyze communication patterns and identify potential conflicts or misunderstandings, enabling proactive conflict resolution.

AI-Powered Supply Chain Dashboard System

This system uses AI to aggregate and analyze data from various sources across the entire supply chain, providing a comprehensive view of key performance indicators (KPIs). This enables proactive identification of bottlenecks, inefficiencies, and potential risks.

| KPI Name | Current Value | Target Value | Status |

|---|---|---|---|

| On-Time Delivery Rate | 95% | 98% | At Risk |

| Inventory Turnover Rate | 6 times/year | 8 times/year | At Risk |

| Order Fulfillment Cycle Time | 3 days | 2 days | At Risk |

| Transportation Costs | $150,000 | $120,000 | At Risk |

The Future of AI in Supply Chain Management

The integration of artificial intelligence (AI) into supply chain management is rapidly evolving, promising significant advancements in efficiency, resilience, and sustainability. Current applications are laying the groundwork for a future where AI plays a central, transformative role, impacting every aspect of how goods and services are moved and managed globally. This section explores emerging trends, ethical considerations, and the potential for AI to create a more sustainable and resilient supply chain.

Emerging Trends in AI and Their Impact on Supply Chain Management

Several key trends are shaping the future of AI in supply chain management. These include the increasing sophistication of machine learning algorithms, the rise of digital twins, the expanding use of edge computing, and the growing importance of data integration and analysis. More powerful machine learning models enable more accurate demand forecasting, improved route optimization, and enhanced anomaly detection.

Digital twins provide virtual representations of physical supply chains, allowing for simulation and optimization before implementation. Edge computing processes data closer to its source, reducing latency and enabling real-time decision-making. Finally, improved data integration across disparate systems unlocks a wealth of insights for better decision-making and process optimization. These advancements collectively promise greater efficiency, reduced costs, and enhanced responsiveness to market changes.

Ethical Considerations Related to AI in Supply Chain Operations

The deployment of AI in supply chain management raises several important ethical considerations. Bias in algorithms, data privacy concerns, and the potential for job displacement are key issues. Algorithmic bias, if not addressed, can lead to unfair or discriminatory outcomes, particularly in areas like supplier selection or workforce management. Protecting sensitive data related to supply chain operations and ensuring compliance with relevant regulations is crucial.

Furthermore, the potential for AI to automate tasks traditionally performed by humans necessitates careful consideration of the societal impact, including the need for retraining and upskilling programs to mitigate job displacement. Proactive measures to address these ethical concerns are essential to ensure responsible and equitable implementation of AI in supply chains.

AI’s Potential for a More Sustainable and Resilient Supply Chain

AI offers significant potential for creating a more sustainable and resilient supply chain. By optimizing transportation routes, reducing waste, and improving resource allocation, AI can contribute to lower carbon emissions and reduced environmental impact. AI-powered predictive analytics can anticipate disruptions, allowing for proactive mitigation strategies and enhanced resilience in the face of unforeseen events such as natural disasters or geopolitical instability.

For example, AI can optimize inventory levels to minimize waste, predict potential supply chain bottlenecks, and facilitate the use of sustainable materials and packaging. This leads to improved efficiency, cost savings, and a reduced environmental footprint.

An Innovative AI-Powered Solution for Reducing Food Waste

A significant challenge in the food industry is reducing food waste throughout the supply chain, from farm to table. An innovative AI-powered solution could leverage computer vision and machine learning to monitor and predict food spoilage in real-time. This solution would involve deploying sensors and cameras in warehouses and distribution centers to capture images and data on food products.

The AI system would then analyze this data to identify patterns indicative of spoilage, allowing for proactive intervention to prevent waste.

- Real-time Spoilage Detection: The system uses computer vision to identify signs of spoilage, such as discoloration, mold growth, or changes in texture.

- Predictive Modeling: Machine learning algorithms predict the shelf life of products based on various factors, including temperature, humidity, and product characteristics.

- Automated Alert System: The system automatically alerts relevant personnel when spoilage is detected or predicted, enabling timely intervention.

- Inventory Optimization: The system helps optimize inventory management by predicting demand and minimizing overstocking, a major contributor to food waste.

- Data-Driven Insights: The system provides valuable data-driven insights into spoilage patterns, allowing for improvements in storage, handling, and transportation practices.

This AI-powered solution could significantly reduce food waste, improve efficiency, and enhance the sustainability of the food supply chain. The system’s ability to predict and prevent spoilage would lead to substantial cost savings for businesses while also contributing to a more environmentally responsible food system.

The integration of AI into supply chain management is no longer a futuristic concept; it’s a present-day reality driving significant advancements. While challenges remain, the potential benefits – increased efficiency, improved decision-making, enhanced resilience, and greater sustainability – are undeniable. As AI technologies continue to evolve, their impact on supply chain operations will only deepen, leading to a more streamlined, responsive, and ultimately more profitable industry.

Embracing AI is not just an option; it’s a strategic imperative for businesses aiming to thrive in the competitive landscape of modern logistics.

FAQ Insights

What are the biggest risks associated with implementing AI in supply chain management?

Significant risks include high initial investment costs, data security and privacy concerns, integration complexities with existing systems, and the need for skilled personnel to manage and maintain AI systems. Additionally, the potential for algorithmic bias and the ethical implications of AI-driven decisions must be carefully considered.

How can companies ensure the ethical use of AI in their supply chains?

Ethical considerations should be embedded throughout the AI implementation process. This includes using diverse and representative datasets to mitigate bias, establishing clear guidelines for data privacy and security, promoting transparency in algorithmic decision-making, and ensuring accountability for AI-driven outcomes. Regular audits and ethical reviews are crucial.

What is the return on investment (ROI) for AI in supply chain management?

ROI varies greatly depending on the specific application and the scale of implementation. However, potential returns include reduced operational costs (inventory, transportation, labor), improved forecasting accuracy leading to less waste, increased efficiency through automation, and enhanced customer satisfaction through faster delivery and better service.